HIGH-PRESSURE COOLANT SYSTEMS

.png?width=500&height=500&name=FILTRATION%20SYSTEM%20PAGE%20-%20ULTRAFLEX%20BASE%20MODEL-min%20(1).png)

Increase Throughput by 30% with CoolJet High-Pressure Coolant Systems!

The CoolJet high-pressure coolant system utilizes state-of-the-art technology, helping customers keep their machine tool spindles running and profits flowing!

- Increase speeds and feeds by 20% or more

- Increases coolant life and protects your machine tool with superior filtration

- Increase tool life 3x to 10x

- Smaller space-saving design and footprint than our competitors

- Modular design allows unit build flexibility that our competitors can’t match

- Easy to maintain - no tools needed or no downtime required for filter changes

The Benefits of High-Pressure Coolant

High-pressure coolant systems offer significant advantages in manufacturing. Firstly, HPC effectively removes heat from the cutting zone, by penetrating the vapor barrier which reduces thermal deformation preventing excessive wear and tear on your cutting tool leading to more precise and consistent machining results. Additionally, the high-pressure stream flushes away chips from the work surface, preventing chip re-cutting and potential damage to the workpiece and machine tool.

If you are milling, turning, grinding, or drilling, high-pressure cooling will help you with:

- Improved Chip Management

- Increased Speed & Feeds

- Increased Tool Life

- Superior Filtration to Increase Coolant Life

- Improved Part Finishes

See CoolJet High-Pressure Coolant in Action

High-Pressure Face Milling

High-Pressure Boring

High-Pressure Part Cutoff

High-Pressure Drilling

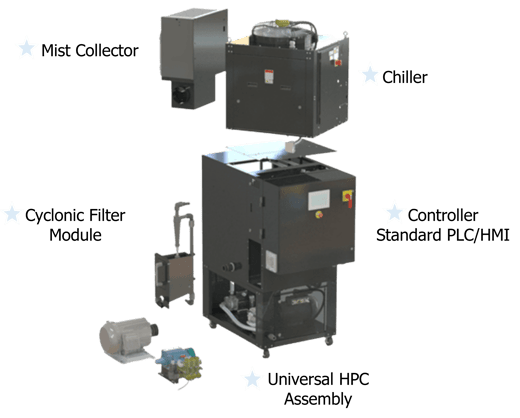

FULLY MODULAR - "Have it Your Way"

The most versatile and innovative high-pressure coolant system on the market. Available in fixed and variable flows.

Increase Your Bottom Line with CoolJet HPC Systems

CoolJet UltraFlex®

The CoolJet Systems are Ideal High-Pressure Coolant Systems for Your Machine Tools

The UltraFlex® can be ordered with fixed or automatic variable volume and single or variable pressure settings. The UltraFlex® has two high-pressure outlets as a standard with up to 8 available, with a range of 300 psi to 3000 psi (20 Bar to 210 Bar) of pressure and volumes from 4gpm to 20gpm (15lpm to 80lpm). The UltraFlex® System will increase your facility's productivity.

Standard features of the UltraFlex® high-pressure coolant system include an onboard feeder pump, a large color touchscreen operator display, a 65gal / 250L clean tank, quad high-capacity quick-change 10-micron filters, interface cables, and hoses. They can be built for 240-volt or 480-volt power sources. All this is a compact footprint of 24" x 56" x 63".

You can configure your UltraFlex® unit filtration and add unit-integrated accessories like a 36,000 BTU Chiller, 850 CFM mist and smoke collector, oil skimmer, and Cyclonic or Magnetic filtration.

The CoolJet TL®

The CoolJet TL® is a fixed-volume, single-pressure unit.

The CoolJet TL® has one high-pressure outlet, with a range of 300 psi to 1000 psi (20 Bar to 70 Bar) of pressure and a 9gpm volume (36lpm).

Standard features of the CoolJet TL® high-pressure coolant system include an onboard feeder pump, color touchscreen operator display, dual-parallel 10-micron filters, interface cables, and hoses. They can be built for 240-volt or 480-volt power sources.

- 9.5 gpm / 36 lpm fixed flow

- Range of 300 psi

- Single outlet

- Dual parallel 10-micron bag filtration

- Footprint: W - 24” x L - 32” x H - 35”

W - 610 mm x L - 812 mm x H - 889 mm - Power to Spec — 230v / 460v / 400v KVA – 5.9

Unit Options:

- Ethernet IP Machine Interface available

.png?width=500&height=500&name=FILTRATION%20SYSTEM%20PAGE%20-%20COOLJET%20TL-%20Copy-min%20(1).png)

Available CoolJet Models

| Ultraflex |

Series | |||||||

| Unit Series | Volume | Pressure | Flow Type | Unit Configuration | Unit KVA | Outlets |

Filtration Type | |

| 70-36 | 9gpm 36lpm | 300-1000psi 20-70bar | Fixed or Variable | Base Model | 10.85 | 2 | Up to 8 | 10um Bag or 5um Cyclonic |

| Mist Collector | 11.64 | |||||||

| Chiller | 21.20 | |||||||

| Chiller & Mist Collector | 22.00 | |||||||

| 70-60 | 16gpm 60lpm | 300-1000psi 20-70bar | Fixed or Variable | Base Model | 14.38 | 2 | Up to 8 | 10um Bag or 5um Cyclonic |

| Mist Collector | 15.18 | |||||||

| Chiller | 24.66 | |||||||

| Chiller & Mist Collector | 25.46 | |||||||

| 55-75 | 20gpm 75lpm | 300-750psi 20-55bar | Variable | Base Model | 14.38 | 2 | Up to 8 | 10um Bag or 5um Cyclonic |

| Mist Collector | 15.18 | |||||||

| Chiller | 24.66 | |||||||

| Chiller & Mist Collector | 14.50 | |||||||

| UD SERIES - DUAL HIGH-PRESSURE PUMP MODEL | ||||||||

| 70-36-2 | 19gpm 72lpm | 300-1000psi 20-70bar | Fixed or Variable | Base Model | 17.74 | 4 | Up to 8 | 10um Bag or 5um Cyclonic |

| Mist Collector | 18.53 | |||||||

| Chiller | 28.10 | |||||||

| Chiller & Mist Collector | 28.89 | |||||||

| SWISS MODELS | ||||||||

| 140-20 | 5gpm 20lpm | 300-2000psi 20-140bar | Fixed or Variable | Base Model | 11.25 | 2 | Up to 8 | 10um Bag or 5um Cyclonic |

| Mist Collector | 12.04 | |||||||

| Chiller | 21.60 | |||||||

| Chiller & Mist Collector | 22.40 | |||||||

| 210-15 | 4gpm 15lpm | 300-3000psi 20-210bar | Fixed or Variable | Base Model | 14.26 | 2 | Up to 8 | 10um Bag or 5um Cyclonic |

| Mist Collector | 15.06 | |||||||

| Chiller | 25.08 | |||||||

| Chiller & Mist Collector | 25.88 | |||||||

.png)

.png?width=114&height=50&name=ATS-Old-Site%20(1).png)